Jeremy Ficca: Fabricating Customization Seminar

OVERVIEW

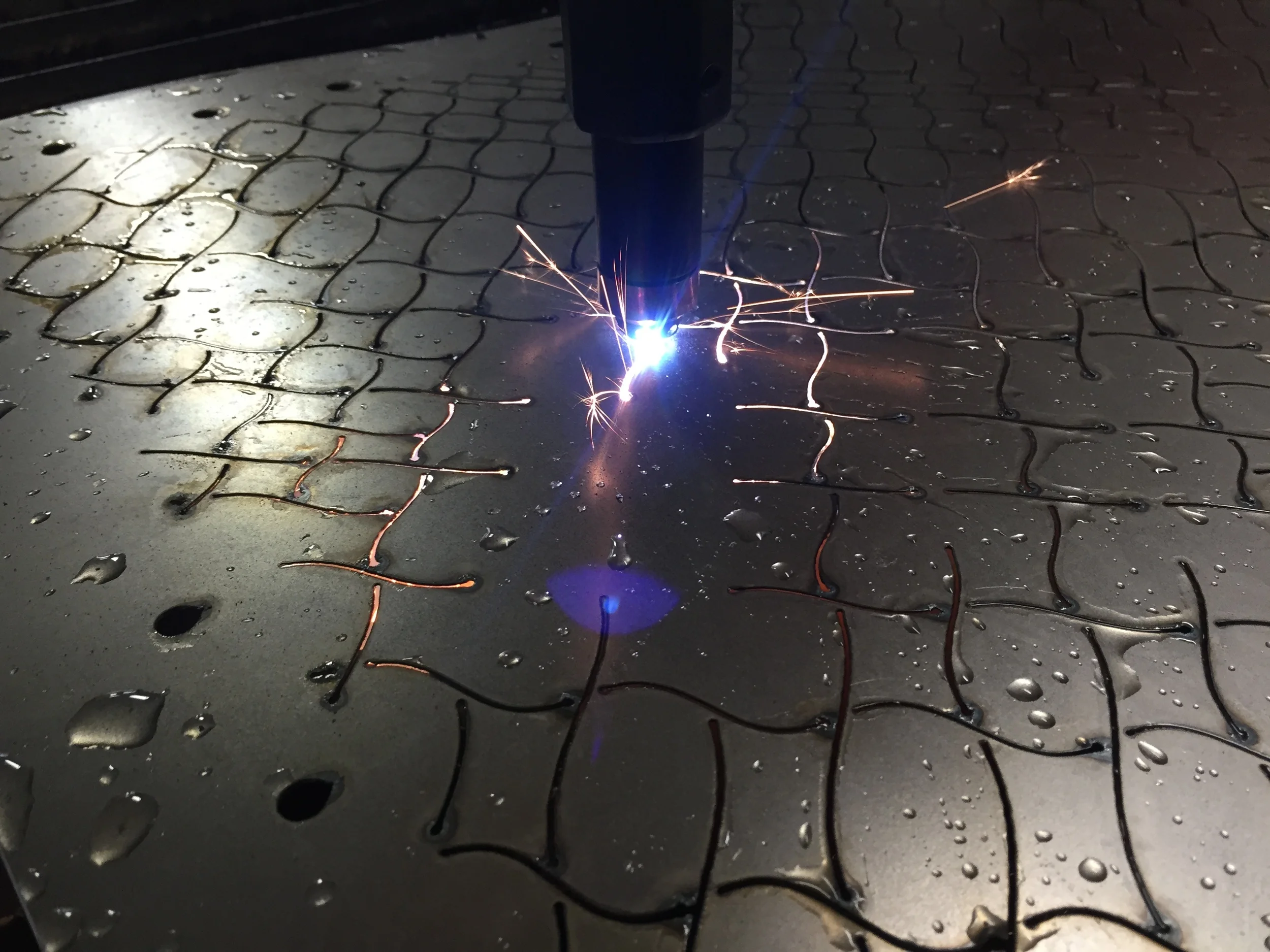

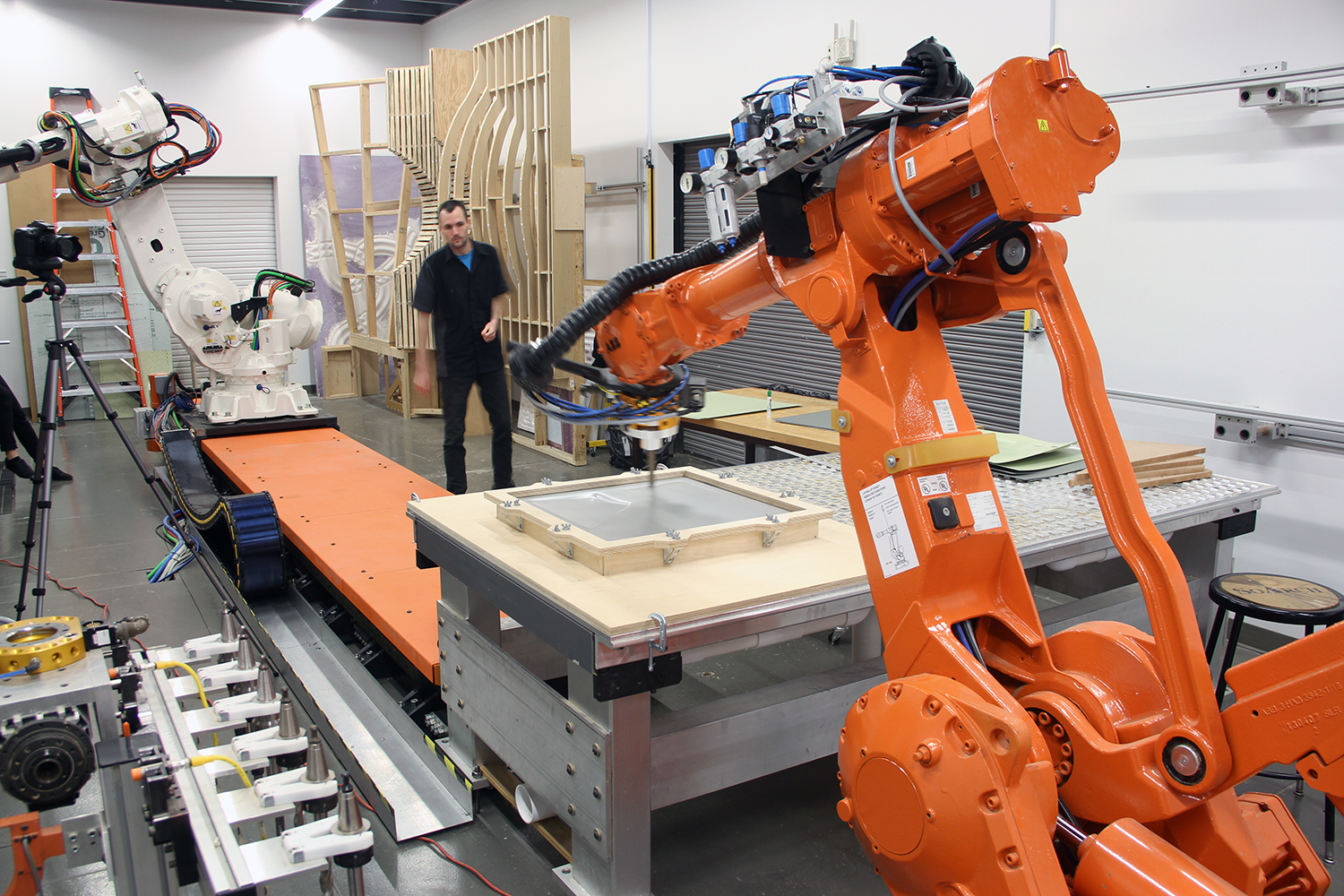

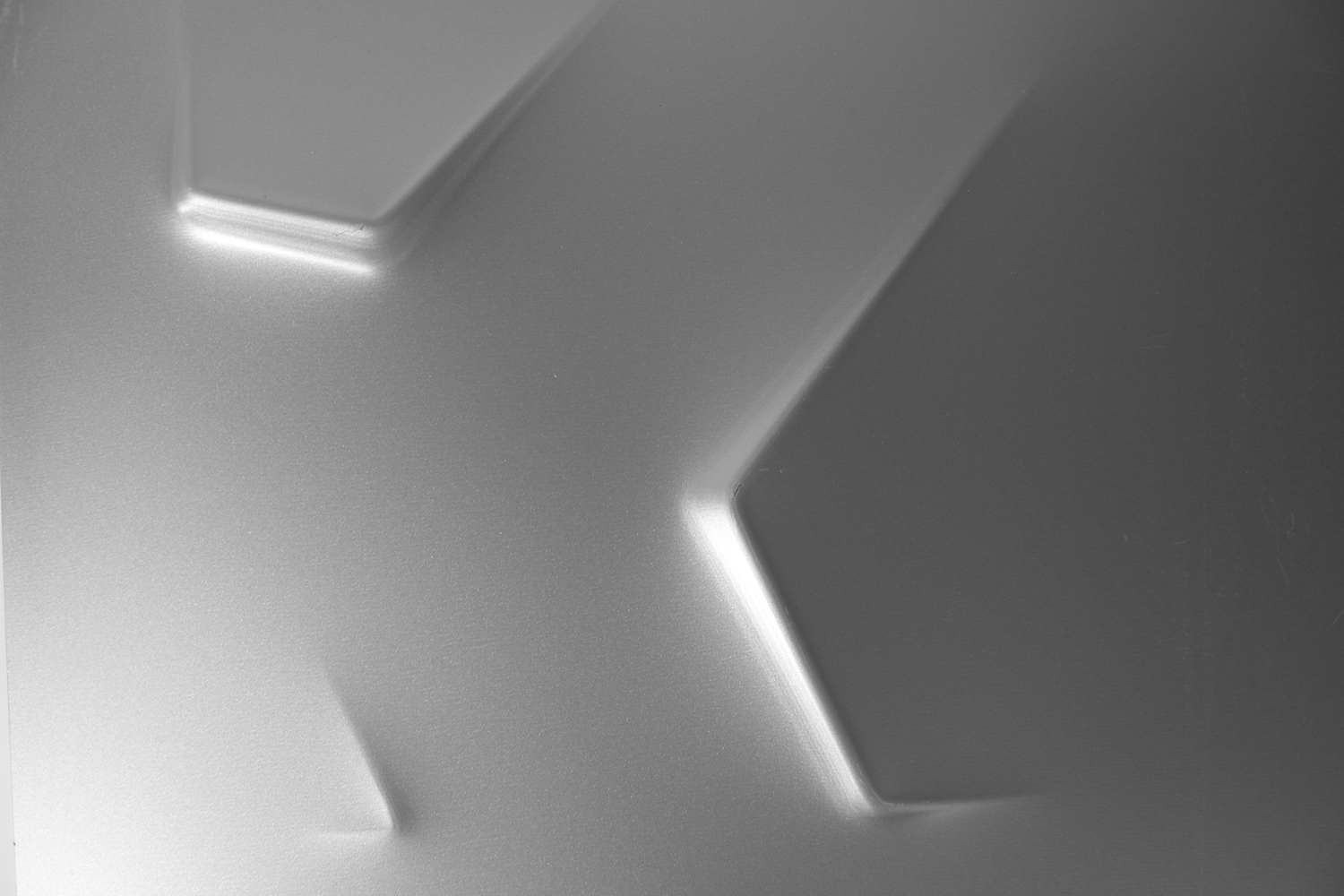

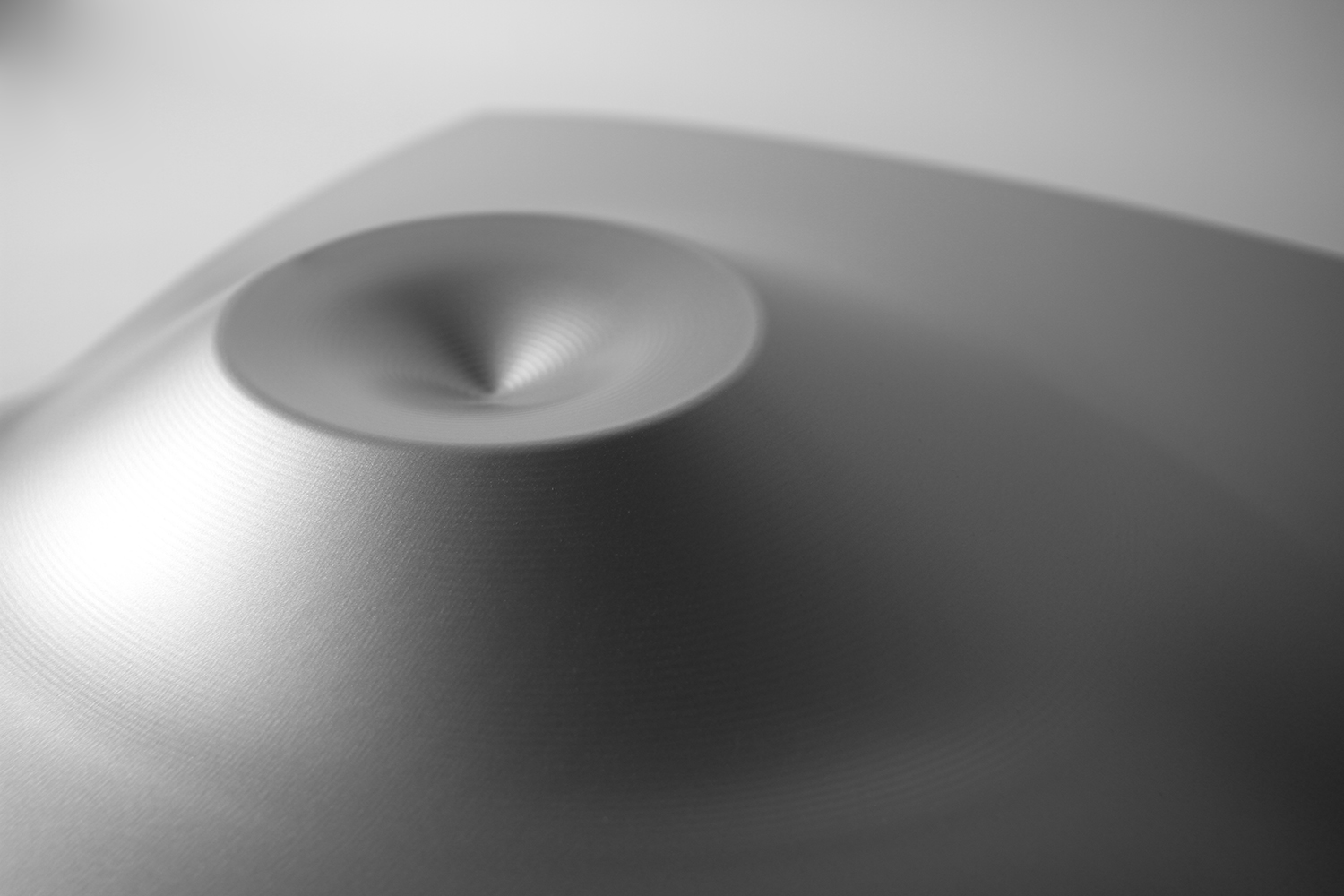

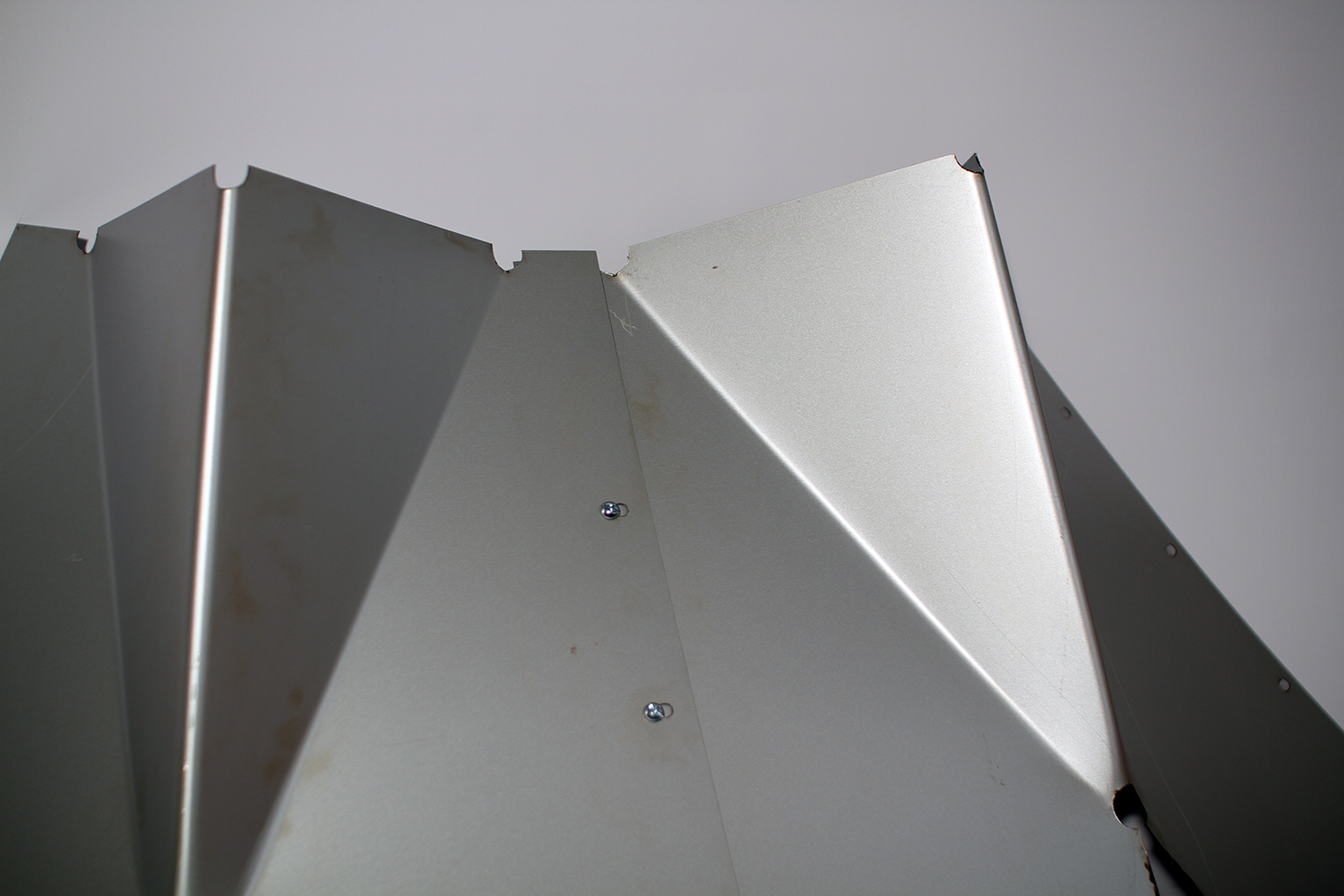

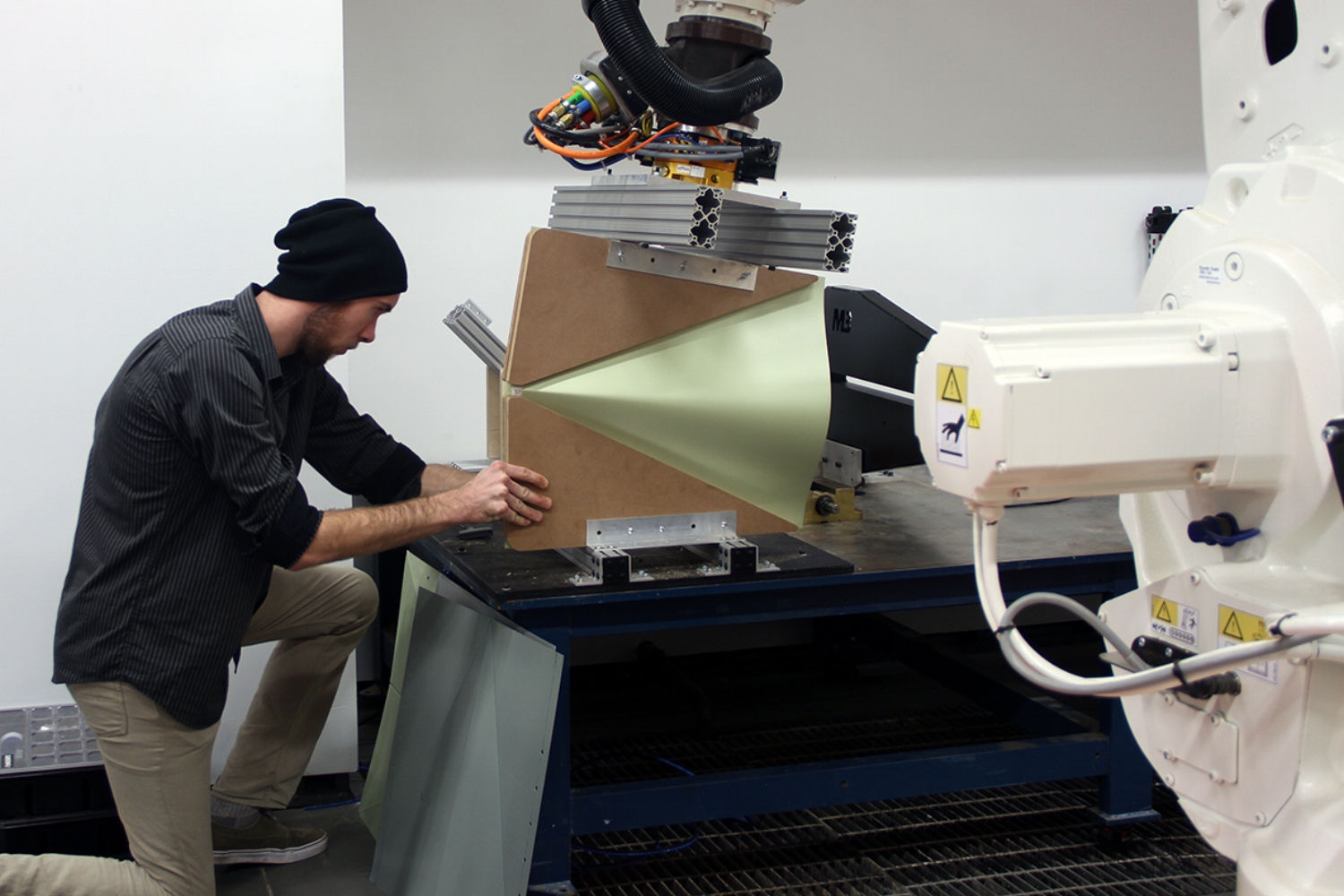

Professor Ficca's seminar relocates the design process from the studio to the lab-workshop, moving design decisions upstream to include considerations of tooling and material processing as inputs for design experimentation. In the fall of 2015, student teams explored novel methods of robotic sheet metal forming that were borne out of direct experimentation with industrial robotic arms and customized metal forming tools. The course was driven by two primary motivations: 1) Explore novel methods of customizable robotic metal sheet forming. 2) Speculate upon the potential application of the results at the building scale.

The work leveraged the robustness and precision of industrial robotic arms in conjunction with rule-based, computationally generated geometry to explore highly customizable alternatives to longstanding mass-production metal forming techniques.

In situating the course as a series of open-ended design experiments, rather than product designs, the students produced artifacts that reveal the methods of their production and uniqueness of their material character.

RESEARCH BY DESIGN PROCESS

Fabricating Customization is conducted as an advanced research seminar in which design, prototyping and fabrication are interrelated and complementary endeavors. Students pursue prescient research in methods of robotic fabrication and the reciprocal relationship between design and fabrication.

In the fall 2015, Centria, a leading manufacturer of metal building facade systems, served as the industry partner, providing expertise as well as financial and material support.